Additive manufacturing: 3D printing technique that creates objects by repeatedly building super-fine layers on top of one another.

When we couldn’t locate an easy-to-use software choice that met our wants , we created it.

Developed solely for GE Additive equipment, Amp integrates the various tools engineers need to manage, process and manufacture metal additive parts in one integrated platform—built on GE’s expertise and encounter.

Nonprofits and cities around the world are turning to 3D printing to solve the worldwide homeless crisis.New Storyline, a nonprofit focused on creating better living situations, built the initial 3D-printed local community in Mexico.

Do you know the best manufacturing techniques for creating original prototypes?

This article covers the main element great things about prototyping with technology like FDM, SLA and sheet metallic fabrication and how exactly to save money and time with one of these processes.

LOM is quite cost-effective because of the ready availability of all the raw materials.

Having less pre-production preparation means the printers are also very fast.

LENS utilizes a deposition brain consisting of a laser head, powder dispensing nozzles, and inert gas tubing.

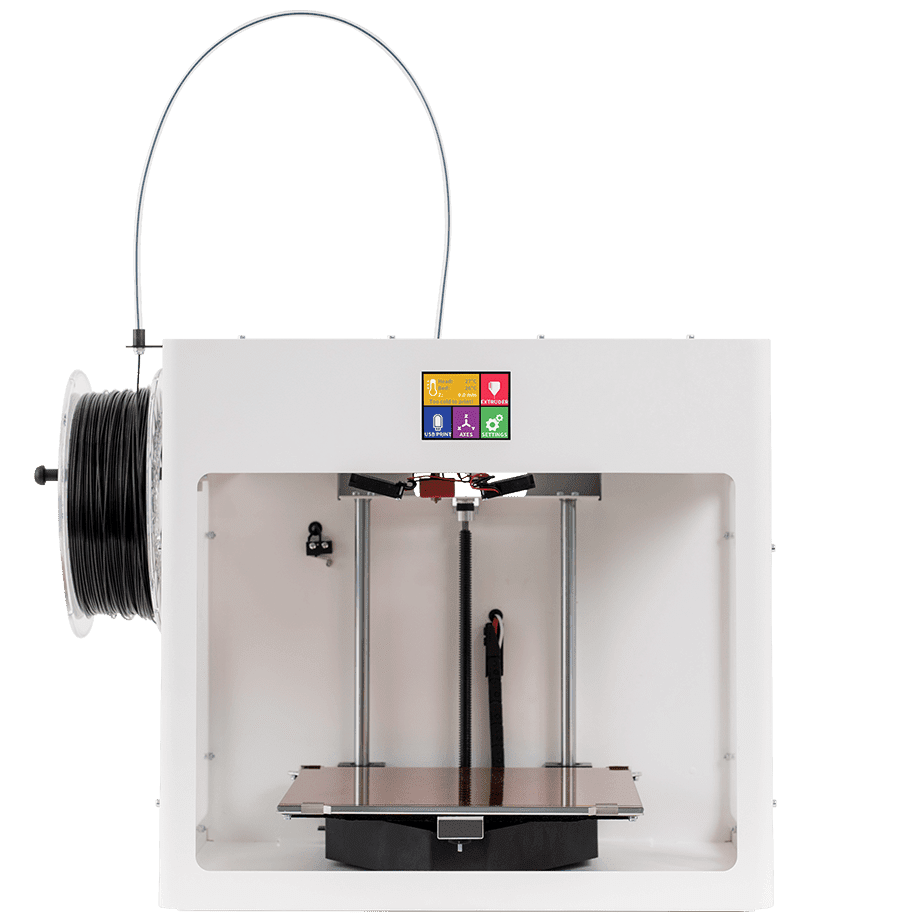

3D printing uses specific equipment to generate solid, three-dimensional objects from a digital file.

The practice has been around because the 1980s, when Charles W. Hull invented the procedure and created the first 3D-printed part.

Since then, the field of 3D printing is continuing to grow exponentially and holds many possibilities.

Binder jetting was created in 1993 by Ely Sachs and Mike Cima at the Massachusetts Institute of Systems.

In 1995, Z Corporation acquired the licensing because of this additive manufacturing process.

As time progresses, you can find progressively more uses for 3D printing that shows light of phenomenal activities thanks to the usage of 3D printers.

Many people believe 3D printing will announce a revolution in the making industry and the planet economy.

In 2012, by adding plastic along with other various materials for 3D printing, several authors begun to believe that 3D printing could possibly be important for a developing world.

3D printing is an additive manufacturing process that uses thin layers of filament to produce a physical object from a three-dimensional model.

An electronic file creates the type which finally transfers to the printer.

The 3D printer makes thin layers, one on top of another, until a 3D printed object is formed.

The 3rd major printing method is SLS, which uses a powdered raw material, typically a polymer.

The powder is stored in a container, where a recoating blade distributes a thin layer of stuff onto the build place.

The attempt occurred at the Battelle Memorial Institute in Columbus, Ohio, USA .

During this pioneering experiment, two laser beam beams with non-similar wavelengths have been pointed to intersect in the middle of a transparent container filled up with of resin.

Inside the vat of resin , the polymer crosslinked and solidified at the main point where the laser beams intersected.

- Some resins, like transparent kinds, require additional post-processing to attain the best visual benefits or, regarding clear resins, optical clearness.

- Introducing preventive engineering procedures, proper printer design, and proper ventilation can help reduce risks.

- A downside to building an item up layer by layer, is that this can affect the durability and strength of the object.

- 3D printing offers easy-to-use desktop computer printers, which are increasingly popular among institutions and engineers.

However, because help structures are not necessary, interior structures are possible.

The powders are usually commercial off-the-shelf materials created for welding and are accessible.

But for simple parts, traditional developing is still more often than not cheaper.

natural level from the diameter of a human head of hair to the height of a single sheet of paper.

3D printing enables makers and engineers, who are creating objects with few tolerances and design information, to create products and bright suggestions real.

In every case, 3D printing is changing business design innovation in a very rapid manner .

The benefits of 3D printing technologies will continue steadily to emerge through continuing exploration efforts, which should be undertaken to understand and eliminate constraints that inhibit the use of this technology.

- As well, the

- Till now, probably the most widely on the globe, 3D printing can be used in the aerospace sector.79, 80 This market makes use of AM not only for inside and cockpit equipment parts, but recently also for pieces used in aircraft engines.

- Educational institutions lead many R&D initiatives, though students as early as kindergarten age are actually likewise finding 3D printers within their classrooms.

3D publishing has enabled on-demand developing which has result in lower stock levels and has shortened design and manufacturing cycles.

In the auto sector, AM’s rapid prototyping prospective garners serious attention as production pieces are appearing.

Trending Topic:

Market Research Facilities Near Me

Market Research Facilities Near Me  Cfd Flex Vs Cfd Solver

Cfd Flex Vs Cfd Solver  Best Gdp Episode

Best Gdp Episode  Tucker Carlson Gypsy Apocalypse

Tucker Carlson Gypsy Apocalypse  Stock market index: Tracker of change in the overall value of a stock market. They can be invested in via index funds.

Stock market index: Tracker of change in the overall value of a stock market. They can be invested in via index funds.  Arvin Batra Accident

Arvin Batra Accident  CNBC Pre Market Futures

CNBC Pre Market Futures  90day Ticker

90day Ticker  Phil Town Portfolio

Phil Town Portfolio  Robinhood Customer Service Number

Robinhood Customer Service Number