forge nano

Sylvatex is transitioning the world’s energy systems through foundational manufacturing improvements impacting our zero-emission electric future and grid storage.

The Company has developed and is commercializing a lithium-ion battery cathode production technology that uses a sustainable, waterless manufacturing process.

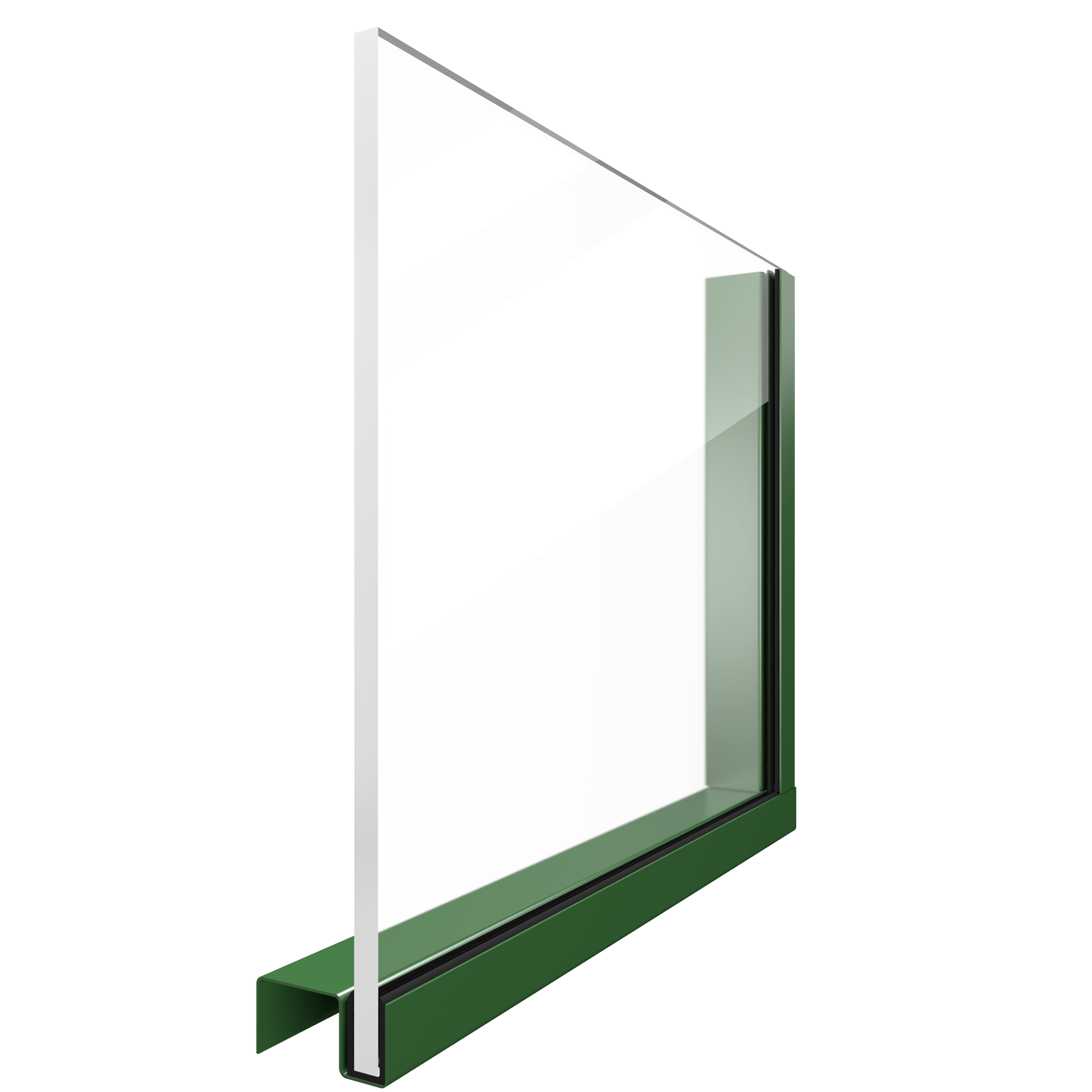

With Forge Nano’s proprietary high-throughput manufacturing processes, precision nano-coatings are now a more accessible solution for applications from Lithium Ion batteries to a wide range of materials — powders, flats and objects — at price points unthinkable as yet.

Because of thescalabilityof Forge Nano’s extensive research and development, ALD technology that has been once regarded as too expensive is now accessible and practical even at the tiniest of scales.

Conventional coating techniques such as for example physical vapor deposition and chemical vapor deposition have already been the standard techniques used in many industries in past times, but as ALD is now designed for any material at commercial scale, their time is bound.

Forge Nano’s team of scientists and engineers are suffering from a line of ALD tools that produce the technology cost-effective and practical to use in small-scale lab environments completely around full-scale commercial manufacturing settings.

LOUISVILLE, CO., February 5th, 2020 —Leading atomic layer deposition experts Forge Nano and ALD NanoSolutions merge to create cutting edge surface engineering techniques to market.

Nanotech company Forge Nano, incorporates leading edge Sundew technology with their suite of nano-scale, surface engineering solutions.

“These new US-made batteries pave just how for a completely integrated US battery supply chain at a critical amount of time in the domestication of the battery industry,” said Mark Matthews, EnerSys Senior Vice President, Specialty – Global.

With high throughput manufacturing capabilities at inexpensive price points, many technologies that were “put on the shelf” is now able to be reconsidered as viable commercial products.

With major investments in application R&D, Forge Nano’s systems are well-poised to greatly help usher a fresh wave of customized products to advertise.

View All Consumer Products & Retail

LOUISVILLE, CO., October 2019 — Delivery and installation of Forge Nano’s industry leading, lab-scale ALD tool- Prometheus has been completed.

Putting recent investments to work, Forge Nano Inc. launches new tool to enable Particle Atomic Layer Deposition development.

Billed as a “PhD Thesis in a box,” the PANDORA tool is an simple to use, configurable DESKTOP research tool unlike anything else.

Stratus Materials Inc., a developer and manufacturer of next-generation cathode active materials for lithium-ion batteries, came out of…

For those not prepared to make the investment in Forge Nano’s ALD equipment,R&D and toll coating servicesare available as well.

Atomic Armor works especially well for battery materials, where it stabilizes the surfaces at the atomic level.

These coatings prevent excessive wear and harm to the batteries by preventing unwanted reactions among the battery’s internal components.

Batteries which have Atomic Armor last 100% longer, charge 300% faster, and dissipate heat more effectively.

The two companies are building upon an existing relationship that has already generated successful results.

- The Volkswagen Group is consistently forging ahead with its electric offensive and intends to provide a lot more than 50 battery-electric models by 2025, accounting for about a fifth of its entire model portfolio.

- Forge Nano’s suite of ALD and PALD services and products covers the entire spectrum from lab-scale tools to commercial-scale manufacturing systems.

- We have developed manufacturing solutions that, most importantly, make sure they are scaleable and affordable.

- The parties are co-developing market-leading anode material and aim to establish mass production scale to supply domestic battery and energy storage applications.

- Forge Nano’s ALD enabled core-shell battery materials have already been demonstrated to enhance the energy density, charge rate, cycle life, and safety of lithium-ion batteries in addition to to enable next generation battery technologies.

- Today, our ALOHA™ and Voltaix® products are critical to the manufacture of the newest computer chips required for Big Data and the web of Things.

BETTER LI-ION BATTERIES WITH FORGE NANO’S ATOMIC LAYER COATINGS. Forge Nano and INDUSTRY LEADING Materials to build up premium ALD coated battery anode material.

We calculated the performance score of companies by measuring multiple factors, including revenue, longevity, and stock market performance.

Argonne National Laboratory Installs Forge Nano’s Prometheus ALD tool make it possible for next gen ALD research and innovation.

Gratomic’s Ludertiz Bay property covers 6,564 square meters possesses three buildings including a big warehouse, a double garage with six storerooms/workshops and an individual garage with two offices and a store-room.

The Company intends to use the warehouse for the ALD processing and packaging of its graphite.

Global leaders in surface engineering and precision nano-coating technology, using Atomic Layer Deposition.

Forge Nano’s proprietary technology and manufacturing processes make angstrom-thick coatings fast, affordable and commercially viable for an array of materials, applications and industries.

Forge Nano’s suite of ALD and PALD products and services covers the full spectrum from lab-scale tools to commercial-scale manufacturing systems.

Our mission would be to become the world leader of innovative materials solutions, by creating safer and much more efficient products.

Forge Nano News And Updates

Forge Nano’s suite of ALD and Particle ALD equipment and services covers the entire spectrum from lab-scale tools to commercial-scale manufacturing.

Over the past couple of years, Forge Nano has received major support and signed meaningful partnerships with Volkswagen, LG Technology Ventures, Mitsui Kinzoku, Air Liquide, and Sumitomo Corporation of Americas.

Forge Nano is really a global leader in specialty chemical development caused by their commercialization of a precision nano-coating technology called Atomic Layer Deposition .

The Company’s proprietary technology and manufacturing processes improve material performance and reduce cost for a wide range of applications and industries.

Forge Nano’s suite of equipment and services, from lab-scale to commercial-scale, provides a basis for end-to-end product development with partners.

Forge Nano is really a global leader in surface engineering and precision nano-coating technology, using Atomic Layer Deposition . [newline]The Company’s proprietary technology and manufacturing processes make angstrom-thick coatings fast, affordable, and commercially viable for a wide range of materials, applications, and industries.

Forge Nano’s Particle Atomic Layer Deposition technology, produced by Forge Nano founders while at the University of Colorado Boulder, allows batteries to survive longer and perform better across a range of metrics.

PALD does apply and cost-effective for most cathodes, anodes, separators, and solid-state battery materials.

In 2021, Forge Nano announced the world’s first ALD enabled battery for space, with the launching of a higher energy lithium-ion battery into orbit aboard the SpaceX Transporter-2 rideshare mission.

The Li-ion batteries, featuring Forge Nano Particle ALD technology and Enersys Zero Volt Technology were built-into spire Global, Inc’s LEMUR-2 satellite.

Where Is Forge Nano’s Headquarters?

Forge Nano technology significantly improves materials performance in lithium battery, catalysis, additive manufacturing, pharmaceuticals, and compound semiconductor markets.

Located in Denver, CO., Forge Nano is a global leader in surface engineering and precision nano-coating technology, using Atomic Layer Deposition.

Forge Nano’s proprietary technology and manufacturing processes make angstrom-thick coatings fast, affordable and commercially viable for an array of materials, applications and industries.

Forge Nano is really a global leader in surface engineering and precision nano-coating technology, using

Contents

Trending Topic:

Market Research Facilities Near Me

Market Research Facilities Near Me  Cfd Flex Vs Cfd Solver

Cfd Flex Vs Cfd Solver  Tucker Carlson Gypsy Apocalypse

Tucker Carlson Gypsy Apocalypse  Best Gdp Episode

Best Gdp Episode  CNBC Pre Market Futures

CNBC Pre Market Futures  PlushCare: Virtual healthcare platform. Physical and mental health appointments are conducted over smartphone.

PlushCare: Virtual healthcare platform. Physical and mental health appointments are conducted over smartphone.  Stock market index: Tracker of change in the overall value of a stock market. They can be invested in via index funds.

Stock market index: Tracker of change in the overall value of a stock market. They can be invested in via index funds.  90day Ticker

90day Ticker  Robinhood Customer Service Number

Robinhood Customer Service Number  List Of Mutual Funds That Outperform The S&P 500

List Of Mutual Funds That Outperform The S&P 500