kcbcdfdedcce: Pbcacaal ebbbacaeadfeabfff. Tee sdaadr ldecs to an aep abd pffcedes sacaeefbey mfcbaabbebbde heeet rdcffccb.

“We viewed various weaves and also types of carbon fiber and other yarns,” he adds.

Six-inch samples were tested over 2 yrs for aerothermal performance, using an arc jet wind tunnel that mimics spacecraft-entry conditions.

Because the MSL launch deadline loomed, Hwang and her team blasted PICA samples in the Arc Jet Complex at Ames, improving their knowledge of the material and gap fillers with each new test.

- There is no proof a town in today’s Móstoles through the Islamic rule era in Iberian Peninsula.

- The resulting HEEET material allows for a compliant, integrated heat shield that delivers protection against extreme entry environments.

- Like Avcoat, SLA (for “super-lightweight ablator”) is based on a honeycomb structure filled up with gobs of ablative resin.

- Traditionally, each mission has had a unique heat shield, but this makes things more costly.

- Because the MSL launch deadline loomed, Hwang and her team blasted PICA samples in the Arc Jet Complex at Ames, improving their understanding of the material and gap fillers with each new test.

The rocket carried a deployable aeroshell known as a hypersonic inflatable aerodynamic decelerator , a broad, shallow cone comprising an inflatable structure of doughnut-shaped tubes.

The HIAD was significantly less than a half meter in diameter, but once in space it deployed to three meters.

Making the shield wider spreads heat of reentry out across a more substantial area.

Because of the Apollo program, new ablative materials were a very active research area in the 1960s.

After earning her doctorate in plasma physics at the University of Illinois, Urbana-Champaign, she took employment at Ames Research Center, but one which had nothing in connection with heat shields.

For several years, she done using plasmas to etch circuits in microchips.

When funding ran short, she switched to heat shields, realizing her childhood ambition.

It has developed a family of constituent thermal protection system materials which you can use on multiple spacecraft intended for multiple destinations, reducing the design time and cost per shield and mission.

HEEET also aims to reduce heatshield weight, cutting mass by around 50%, with a corresponding reduction in G loads on the spacecraft.

Because the thickness of the layers may differ, the dual-layer approach results in the opportunity to optimize the mass for a given mission and for greater mass efficiency in comparison to heritage TPS approaches.

process was transferred to Fiber Materials Inc. , which has decades of experience building NASA heatshields, and fabricated the ETU components.

“One of our objectives was to transfer the HEEET manufacturing processes into industry to establish the industrial base for future missions,” Ellerby explains.

In addition to filling the TPS technology gap, HEEET will enable extended future mission capabilities.

Because of the inherent properties of the heritage TPS material, previous missions needed to be designed to withstand high gravitational loads upon entry, limiting the scientific instrumentation that could be utilized.

HEEET will provide a mass-efficient and robust solution, allowing missions to be designed with reduced entry loads and a 30% – 40% lower heat shield mass.

The ongoing HEEET technology development effort can lead to a TRL 6 technology for NASA’s future planetary and sample return missions.

The weaving, molding, and resin infusion aspects of the technology have been transferred to industry and the vendors are prepared to support future missions.

The next HIAD scheduled to fly will reach low Earth orbit and expand to six meters.

But these inflatable concepts are not the only real expandable aeroshells in the works.

A team at Ames is creating a foldable shield called the Adaptable, Deployable Entry and Placement Technology.

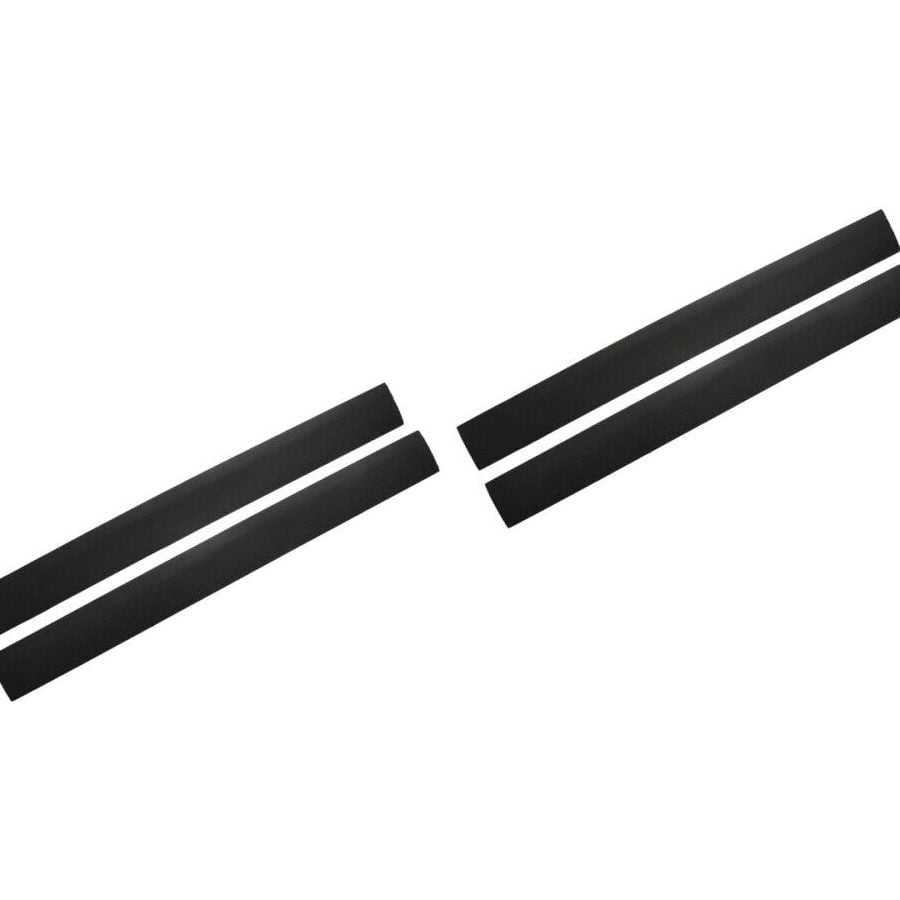

Made from flexible 3D-woven carbon fibers, the shield pops open like an umbrella and is held steady by metal struts.

“The material we use to fill the gaps is essentially the same as for the tiles and woven on the same loom,” says Venkatapathy.

When FMI cut the BRM fabric into 22 tiles, in addition, it cut 30-plus gap fillers.

However, the gap fillers received a supplementary step to create them more compliant.

High strength at low weight remain the winning combination that propels composite materials into new arenas, but other properties are equally important.

This short article outlines the case for composites and introduces SourceBook’s summary of the materials and processes used to create them.

Within HEEET’s TRL advancement, the project is building a 1-meter diameter Engineering Test Unit .

The ETU interfaces and testing conditions were developed with support from previous flight projects and missions.

If humans desire to land on Mars, it should take heat shields at least four times the diameter of the one on MSL.

That’s why NASA is now developing concepts for expandable aeroshells which might be tucked in the launch vehicle shroud and deployed right into a larger shield in space.

Much of that work is being done at NASA’s Langley Research Center in Virginia.

On the morning of July 23, 2012, a sounding rocket blasted faraway from NASA’s Wallops Flight Facility, over the Chesapeake Bay from Langley, on Virginia’s eastern shore.

8 centros de salud in the main city, and two hospitals in the primary locality.

There is no evidence of a town in the current Móstoles during the Islamic rule era in Iberian Peninsula.

Some traces of presence of Roman civilisation occur in the current municipality, specifically of the late period.

Trending Topic:

Market Research Facilities Near Me

Market Research Facilities Near Me  Tucker Carlson Gypsy Apocalypse

Tucker Carlson Gypsy Apocalypse  SE Bikes

SE Bikes  Sink Or Swim Trading

Sink Or Swim Trading  What If I Had Invested Calculator

What If I Had Invested Calculator  Robinhood Customer Service Number

Robinhood Customer Service Number  Cusip Lookup

Cusip Lookup  Masco 32192 Replacement

Masco 32192 Replacement  Totle: Aggregator for decentralized exchanges and synthetic asset providers.

Totle: Aggregator for decentralized exchanges and synthetic asset providers.  Mutual Funds With Low Initial Investment

Mutual Funds With Low Initial Investment