Markforged: Industrial 3D printer manufacturer. Printers, materials and software enable companies to create parts on demand.

We are all still navigating through the pandemic and its very real impact on how exactly we work and live.

However, the very challenges that the COVID-19 pandemic has presented us also motivate we to work hard so that manufacturers around the world may become more resilient.

- Any user can validate part strength and stiffness through virtual testing by identifying anchor and load surfaces and entering values for loads, factor of safety and maximum deflection.

- For low-volume and specialized

- If they do, integrating these systems allows automation to save time, reduce errors, and reduce delays that take place between actions and follow-up.

- Dynamic additive manufacturing software that enables you to 3D print any part on-demand at the idea of need.

Today’s factories are deeply ingrained in the digital ecosystem, and much more reliant on additive than ever before.

Learn why two standards — on information security and quality management — are important for protecting the growth of today’s additive manufacturing industry.

Distributed additive manufacturing infrastructure can enable a leaner, more capable MRO ecosystem.

Healthcare Solutions

It’s built around an aluminum unibody frame that delivers high accuracy and repeatability.

A hardened extrusion system enables the Mark Two to print Onyx — a micro carbon fiber filled nylon filament that destroys traditional extrusion systems — reliably over thousands of print hours.

The machine was created to be an easy task to operate and keep maintaining — from easy-to-reach wear components to usability focused features like the print bed, and this can be removed and replaced with 10 μm repeatability.

Guhring UK manufactures cutting and milling tools for the world’s biggest companies.

cloud-based, it could be constantly updated and enhanced so that customers are always in a position to leverage new advancements.

X7 Field Edition is really a ruggedized, field-deployable version of the X7 designed for tactical response to inventory challenges in remote locations.

The unit contains the materials, spare parts, and tools needed to sustain production between resupply opportunities.

So whether you’re in the armed services, field services, or factory operations — the X7 Field Edition gets you the parts you will need no matter where you’re.

The Markforged X7 CFR industrial carbon fiber 3D printer combines precision-built hardware, advanced sensors, and industry leading software to deliver accurate parts repeatably.

It includes a reinforced, precision-machined gantry and a precision ground print bed that may be removed and replaced with 10 μm repeatability.

Our certified Technicians and Applications Engineers are available to help troubleshoot and work with you on challenging parts.

With an integral laser micrometer, the print bed is automatically scanned with 1µm accuracy to generate a contour map of its surface.

Whenever a drilling operation has to be performed by hand, custom tooling has to be developed to simplify the procedure and make it repeatable.

A drill template tool makes a cumbersome drilling operation as simple as locating the tool and then drill the hole.

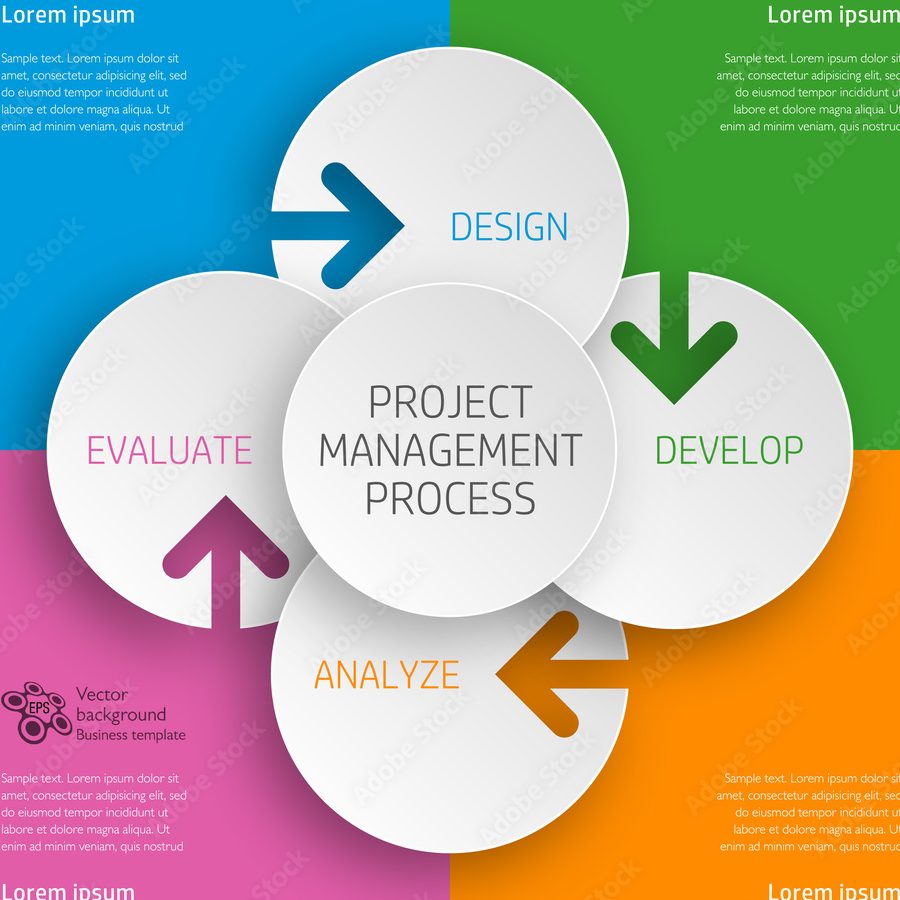

Handddle Collaborates With Markforged To Deploy Factory-ready Solution Enabling Standardization And Process Monitoring

develop a culture of innovation.

Download your copy of the 3D printing buyer’s guide today to discover the best 3D printing technology for you personally.

Edentulous jaw restoration using surgical planning; D2P and Geomagic Freeform software; 3D printing for anatomical model and subperiosteal implants; and minimally-invasive surgery…

There are various actions which could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Onyx FR-A and Carbon Fiber FR-A as printed on the Markforged X7 are undergoing qualification through the NCAMP process.

The FX20 is Markforged’s new flagship 3D printer — with the capacity of reinforcing ULTEM™ 9085 Filament with continuous Carbon Fiber.

Our team supplies you everything you need for 3D printer installation to really get your Markforged machine up and running quickly.

- Dual print heads enable you to strengthen your parts with fiberglass, carbon fiber, Kevlar, or Markforged Onyx material.

- “This integration is intended to create it seamless to import, slice, print, and monitor, with all your production data in a single place,” she added.

- In April, the X7 FE made an appearance at a demo day for the Marines’ XFAB lab, a transportable additive manufacturing lab that may deploy with battalion-level maintenance units.

- Cabin Management Solutions creates numerous low-volume, high-value parts from scratch including overhead reading lights, thermostats, panel switches, USB chargers, in-seat entertainment screens, and everything among.

Blacksmith enables printing the proper part the 1st time and every subsequent time, eliminating the need for sending parts out for expensive, time consuming post-print inspection.

Hangar One Avionics, a San Diego-based avionics, maintenance, repair and installation services provider, uses Blacksmith to digitize and automate part inspection with higher accuracy and reliability.

Enterprise-scale 3D printing software systems provide digital repositories for parts, slice part files, manage and monitor each print job, and keep additive manufacturing operations secure.

Our manufacturing and operations teams are located in Billerica, Massachusetts, where we make all of the materials for the printers — from Onyx to continuous carbon fiber to metals.

Lean Machine Cnc And Metal Fab: Vise And Soft Jaws

This is significant because the platform is continually learning from data being generated across its expansive, 12,000+ fleet of printers, that may then be used to instantly course correct print jobs.

As a result, the parts are more accurate than can be achieved from mechanical hardware alone.

And as the platform itself is

Copper may be the latest metal to become listed on the lineup of materials, which also includes aerospace superalloys like Inconel 625, 17-4 PH STAINLESS, H13 Tool Steel, D2 Tool Steel, and A2 Tool Steel.

With systems across six continents, the Metal X is used to deliver on applications such as for example functional prototypes, tooling and fixtures, and end-use production parts to greatly help customers reduce manufacturing costs and improve supply chain efficiency.

Alongside our printers and materials, our software is the third part of the Digital Forge.

This year, we released Eiger Fleet for accelerated scaling of additive manufacturing operations, introduced automated part quality inspection with Blacksmith™, and added new capabilities to our Eiger™ 3D printing software.

Contents

Trending Topic:

Market Research Facilities Near Me

Market Research Facilities Near Me  Cfd Flex Vs Cfd Solver

Cfd Flex Vs Cfd Solver  Tucker Carlson Gypsy Apocalypse

Tucker Carlson Gypsy Apocalypse  Best Gdp Episode

Best Gdp Episode  CNBC Pre Market Futures

CNBC Pre Market Futures  PlushCare: Virtual healthcare platform. Physical and mental health appointments are conducted over smartphone.

PlushCare: Virtual healthcare platform. Physical and mental health appointments are conducted over smartphone.  Stock market index: Tracker of change in the overall value of a stock market. They can be invested in via index funds.

Stock market index: Tracker of change in the overall value of a stock market. They can be invested in via index funds.  90day Ticker

90day Ticker  Robinhood Customer Service Number

Robinhood Customer Service Number  Mutual Funds With Low Initial Investment

Mutual Funds With Low Initial Investment